When you prepare to connect some SFPs with fiber patch cords, you may find SFPs are multimode modules while your fiber cables are single-mode. Try to connect those optics to fiber cable, but no green light and the link fails. So multimode SFPs can’t work over single-mode fiber cables. To avoid the wasting of time and money, you should better know well about single-mode and multimode SFPs and fiber patch cords.

Single-mode and Multimode SFP

SFP, small form factor pluggable transceiver, can support the data rate up to 1Gbps. SFPs can be divided into single-mode and multimode modules.

For single-mode SFPs, there are “LX” for 1310 nm and “EX” “EZX” for 1550 nm. Single-mode SFPs are designed to transmit signals over long distances. For example, Cisco GLC-LH-SM-15 compatible 1000BASE-LX/LH SFP 1310nm 15km DOM transceiver, main product information is shown as follows:

- Wavelength: 1310 nm

- Interface: LC duplex

- Max Cable Distance: 15 km

- Max Data Rate: 1000Mbps

- Cable Type: SMF

Comparatively, multimode SFPs are identified with “SX”. This kind of optics is specially for short distance data transmission. For instance, Cisco GLC-SX-MM compatible 1000BASE-SX SFP 850nm 550m transceiver, this is a typical multimode SFP.

- Wavelength: 850 nm

- Interface: LC duplex

- Max Cable Distance: 550m over OM2 MMF

- Max Data Rate: 1000Mbps

- Cable Type: MMF

Single-mode Fiber Cable and Multimode Fiber Cable

Fiber patch cables are used to connect transceivers on your switch/device. You have to buy the right fiber cable type for your optics. Fiber cable has two different categories: single-mode and multimode.

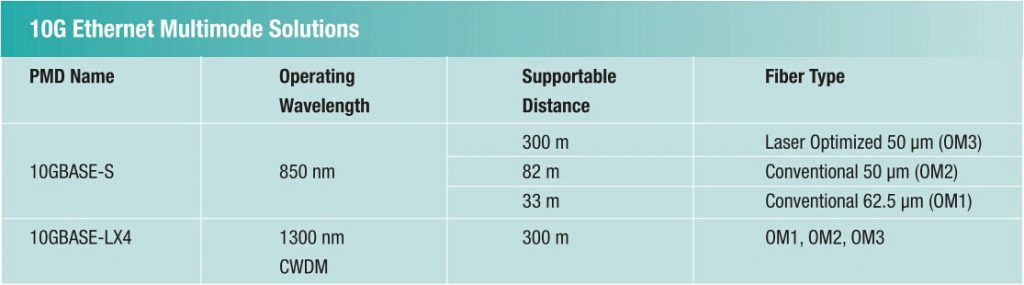

Generally, single-mode fiber cable can support further distance because of lower attenuation, but the price is higher. While multimode fiber cable has a larger core, usually multimode fiber cable is constructed in 50/125 and 62.5/125. It allows multiple modes of light to propagate. When the light passes through the core, the light reflections increases and more data can be transmitted at given time. As the high dispersion during signal transmission, the link distance gets reduced. So multimode fiber cable is for short distance application. Multimode fiber cable is a little more complex than single-mode fiber cable since it includes four different types of OM1, OM2, OM3, OM4. OM1 and OM2 fiber patch cable can support the data rate up to 10Gbps. OM3 and OM4 are laser optimized so that they can be used in high density data center to support the data rate of 40Gbps and 100Gbps. The following table shows how long each kind of fiber cable can reach running at different data rate.

Note: “SR” implies multimode 10Gpbs SFP+.

For more information about single-mode and multimode fiber cable, you can refer to my previous articles:

What Is Single Mode Fiber?

What Are OM1, OM2, OM3 and OM4?

For more information about single-mode and multimode fiber cable, you can refer to my previous articles:

What Is Single Mode Fiber?

What Are OM1, OM2, OM3 and OM4?

Solutions for Multimode SFP

If you have Cisco Catalyst 3650 WS-C3650-48PS switches with 4x1G uplink ports, to build a 300m-network link, you are gonna purchase fiber patch cable and SFP modules. What kind of optical equipment should you choose?

As to the SFP module, you need Cisco GLC-SX-MM 1000BASE-SX SFP. Or you can spend less money on third-party SFPs with 100% compatibility. Next step, you need to find suitable fiber patch cable to match this type of SFP. Since 1000BASE-SX SFP is multimode, of course you need multimode fiber cable. Considering the distance of 300 meters, OM1 can only reach 275 meters. So OM2 is the best choice for it’s the cheapest and can reach 550 meters.

Conclusion

It’s obvious that multimode SFPs can’t work over single-mode fiber cables. When buying SFPs, watch the standards on the label carefully and find if it’s “SX” or “LX”, “EX”. If it shows “SX”, then find multimode fiber patch cable. It’s not very difficult to choose right cable for your SFP modules.

Originally published at www.fiber-optic-equipment.com