Optical networking technology has solved the problem of increasing demand for higher transfer data rates and larger bandwidths. In optical network, optical fiber is the fundamental medium of transmission. However, switching, signaling and processing functions are accomplished electronically. So optical switches are naturally developed. Optical switches are widely used for optical protection, test systems (as shown in the following figure), and remotely reconfigurable add-drop multiplexers, etc.

Figure 1. Switch for FS.COM transceiver compatibility test

Two Types of Optical Switches

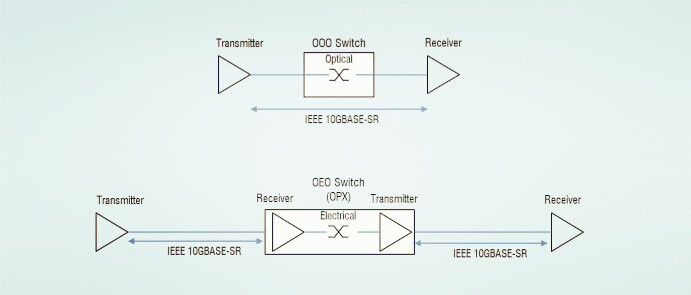

An optical switch is simply a switch which accepts a photonic signal at one of its ports and send it out through another port based on the routing decision made. There are two kinds of optical switches, including O-E-O (optical–electrical–optical) and the O-O-O (optical–optical–optical) also called all optical switch. OEO switch requires the analogue light signal first converted to a digital form to be processed and routed before being converted back to an analogue light signal. While OOO switching is done purely through photonic means.

Advantages of Optical Switches

Compared with electrical switches, optical switches have many advantages.

On one hand, optical switches can save floor space and power consumption significantly. They can save up to 92 percent space and 96 percent power. If translating power savings into cost, it means 3 kw can be reduced for each rack. This can save the carrier from expensive diesel power generators, rectifiers and batteries, the monthly maintenance costs for these devices and the purchasing and maintenance of cooling equipment for these devices.

On the other hand, optical switches are a lot more scalable and faster than electric switches, as all-optical switches are protocol and bit rate independent. Because of the scalability and flexibility all-optical switches have, so transfer rates will not be affected bit rate limitations of switching equipment.

Problems of Optical Switches

Despite those advantages, optical switches still have some problems.

Current optical switching technology can’t realize the technology that photonic signals can be as stored as easily as electrical signals. It is possible to store them using fiber delay lines, as light take a certain time to travel through lengths fiber (200,000 km per second in silica). That means a 10000 bit frame traveling at 10G b/s requires 200m of fiber. This is both expensive and impractical. And once a signal is put through a delay line, it cannot be processed until it comes back out. A solution to this is through adding switches within the lines, but that needs more costs.

The other problem with all – optical switching is that it cannot process header information of packets, especially at such high speed which the signals travel at. The maximum speed electronic routers currently can operate is at 10 Gb/s while optical signals can travel up to 40/100G or even higher. Thus, the routers will not be able to process the signals as fast as the transmission.

Applications of Optical Switches

Optical switches are widely applied in the network.

First, optical switches are used in high speed network which requires very high switching speeds and also requires very large switches to handle the amount of traffic. So switches are likely used within optical cross-connects (OXC). OXC are similar to electronic routers which forward data using switches. An OXC may contain a whole series of optical switches.

Second, optical switches are used for switching protection. If a fiber fails, the switch allows the signal to be rerouted to another fiber before the problem occurs. But this will take milliseconds including detecting the failure, informing the network and switching. Normally this operation requires a 1x2 switch but with complicated cross-connects hundreds may be required.

Third, optical switches can be also used for external modulators, OADM (optical add-drop multiplexers), network monitors and fiber optic component testing.

Conclusion

As the demand for video and audio increasing the challenge of data capabilities and high bandwidth of networks, optical network is absolutely the most cost-effective solution. Optical switches can provide the customers with significant power, space and cost savings. Today, the optical switch market is dominated by several companies, such as Cisco, HP, Arista, Juniper. In early days, original optical transceivers were required to be plugged into these switches. Later, to save the cost, third-party optical transceivers were produced. If you need optical transceivers compliant with these switches, please visit FS.COM.

Originally published at www.fiber-optic-equipment.com